Injector Calibration & Nozzle Mounting (VE)

Description

Digital Injector Calibration

This is the only way to properly set up your new Genuine Bosio nozzles for ideal performance!! This service enables maximum power and efficiency

We feel this is the most technically correct and precise way to maintain and/or upgrade your injection system.

Exclusive Pressure Setting Options :

-

Stage 1- Low Smoke for cleanest operation [ ideal for stock or lightly modified vehicles, or for modified vehicles seeking best fuel economy ]

-

Stage 2 (+5% Main Injection Volume)

=========================

You can send your injectors in for service..... or we offer the very popular and easy KermaTDI Hot Swap Injector Program option

PLEASE NOTE: You will need to order new Bosio injector nozzles when ordering this service. Those nozzles are are located at the fuel shop so if you send your injectors in or do the HOTSWAP program you will not be sent the injector nozzles beforehand. They will simply be installed and calibrated in the injectors.

=======================

Direct Injection (DI) High Tech Injector Rebuilding and Nozzle Mounting and Calibration :

Why is it so important?

Two Stage Injector Calibration

Unlike older IDI or Pintle style injectors, two-stage injectors precisely meter and inject fuel at different intervals of every combustion stroke to control the pressure rise in the cylinder. The resulting softer rise in pressure greatly reduces the Diesel Knock formerly associated with diesel engines. This however results in an injector that cannot be set through conventional methodology. Two stage injectors require multiple steps to ensure both injection events occur within a very narrow window of pressure to ensure that the fuel metering is not affected to maximize the ECUs control of the engine's combustion and power output. Each injection event in normal operation can be as rapid as 1.5 milliseconds in duration while tightly controlling the amount of fuel injected to minimize engine emissions output.

====

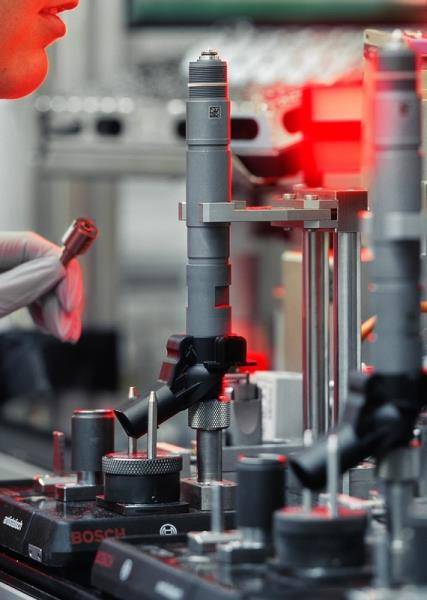

Digital Injector Calibration and Balancing

Digital pressure sensing is used to read and record injector data. The Pressure sensor is certified under ASME B40.7-2005 standards which permits accuracy to +/- 0.5% and a pressure range expanded to over 600 bar! Also due to the high speed cycling of the nozzles the new digital calibration equipment was selected due to its ability to read ALL pressure cycles that occur within a 10-millisecond window! To ensure the highest level of accuracy the pressure resolution will be reduced to .068 bar meaning extremely accurate pressure readings during all injector opening phases that no analog pressure gauge can display.

In House Digital Flow Validation (New for 2011)

Digital flow validation is used to read and set every new nozzle that we sell. This is performed on the nozzles before installation allowing us to ensure that every nozzle performs exactly to specification.

We can generate a complete report for every nozzle and compare every critical aspect of that nozzle's performance. This is the equivalent of a Dyno for nozzles. We can evaluate delivery rate, peak delivery volume as well as response to flow at all ends of the flow range.

This new system uses state of the art Flow sensing technology which evaluates all flow characteristics by replicating the flow of the fuel passing through the nozzle. Long gone are the fill tubes you may have seen, this new generation test bench samples flow rates as often as 400 times per second allowing a complete evaluation of a nozzle performance not previously possible.

This is especially helpful for companies developing a nozzle design or for the performance oriented driver/tuner looking to get the maximum performance from a nozzle combination.

Set Pressure Ranges

Each pressure is set at a predetermined value based on the ECU fuel mappings expectation of injector performance. The pressures of each stage although independent have a reliance on each other to achieve the specified pressure that respective stage should begin to open at. Manipulation of one pressure without adjustment to the other will cause an erroneous pressure change on the other. Anytime one stage is changed the other too must be adjusted and set accordingly.

Spray Quality

Injectors have a certain expectation of durability in a specific application. The primary factor that determines the life of an injector nozzle is the quality of the fuel filtration. peak pressures at the nozzle holes can exceed 2000 bar, any amount of suspended matter can cause the fuel to act like a cutting jet rapidly eroding the nozzle's precision machined hole geometry. It is accepted that no matter how good the filtration is, it is impossible to eliminate all particles from the fuel. So, even with ideal conditions some erosion of the nozzle is expected and will occur thus the reason nozzle fuel spray should be evaluated at regular intervals is to reduce the likelihood of damage to the piston's combustion bowl and cylinders.

Here are the details and the Fine Print goodies:

This is the only way to properly set up your new Genuine Bosio nozzles for ideal performance! This extra attention to correct nozzle/injector technical specifications will optimize performance, smooth engine operation, correct fuel delivery, and provide the best fuel efficiency.

If you'd like upgraded nozzles installed, please select from any of the Genuine Fratelli Bosio nozzles, and add to your order.

You will be emailed a processing form with the address to send the injectors with the Order Confirmation

If you are using our Injector Hot Swap Program we will ship the new Genuine Bosio nozzle mounted and calibrated to you first and then you can return your injector cores to address on the Injector Processing Form.

===============

Hot Swap injector program.

=== Purchase any set of Genuine Bosio ALH nozzles from KermaTDI and pay for Mounting, calibration, and flow balancing and we will ship a set of VE injectors mounted with your nozzles and eliminate downtime of your vehicle.

=== A $600.00 core deposit will be charged at the time of purchase (by typing "HOT SWAP" in the "HOT SWAP DEPOSIT" option above). Once we receive your used set of VE injectors complete and in serviceable condition to us... you will receive your full core charge back without any hidden fees or charges! The core deposit is to ensure that we have good cores for the next customer and can keep these cars running well. This is a group effort to support better running TDI's.

=== Complete injectors mean (3) injectors from cylinders 1, 2, and 4 as well as the #3 injector. The #3 injector is expected to arrive without the T return nipple and banjo bolt. Injectors must be returned unopened and with the nozzles installed to prevent loss of internal components. Note: If you require the nozzles mounted in your core injectors to be returned to you, a modest fee of $10.00 will be charged and the nozzles upon receipt by us will be removed, bagged, and shipped back to you via USPS.

=== Serviceable condition means no marring of the injector bodies such as vice grip marks or other surface damage to the return nipples and threads. The #3 injector must be in good condition without ANY damage, fraying, or tearing of the sensor wire. If there is any damage to the injectors that renders them damaged or unserviceable we reserve the right to retain your full core deposit.

[High deposit level injectors require extra cleaning labor and fluids and may incur a $50 surcharge or cleaning to the required levels may not be feasible. This is most likely to occur with Waste Vegetable Oil or High Concentration Biodiesel... these nozzles and sometimes these injector bodies may not be usable. Please specify if you want these returned to you in the documents when you ship to us ]

=== Note: To prevent damage to the injectors you must remove the injectors using a slide hammer thus extracting them upward and out of the head. This will prevent damage to the injectors and allow easy and quick extraction with minimal effort. This extractor is available for purchase at low cost through KermaTDI and there are plans to make your own on the net. In either case, using this extraction method is the surest way to remove the injectors without damage.

=== We ask that you return the injectors promptly so we can keep this program in full stride. After 90 days the deposit will be forfeited unless arrangements have been made.

=== We realize that at times injectors may be damaged we would like to remind you that we offer a complete set of NEW injectors at very competitive prices shipped to you ready for installation.

Please indicate the year of your vehicle above, as there is a different #3 injector wire connector on most 2003 VWs [D-shaped] Please check this connection before ordering the Hotswap program so we ensure we get you the correct connection [ 1996 to 2002 have a Square Plug on the #3 Injector wire / 2003 usually has a D shaped plug]

------------------

Reviews / Q&A

Details

- Injectorcalib

- Injectorcalib

- KermaTDI

- New

Categories

Shipping Information

- Item Requires Shipping

- 5.0 lbs.

- W5.0000” x H5.0000” x L2.0000”

- Free Ground or Postal Service Shipping to the Continental U.S.